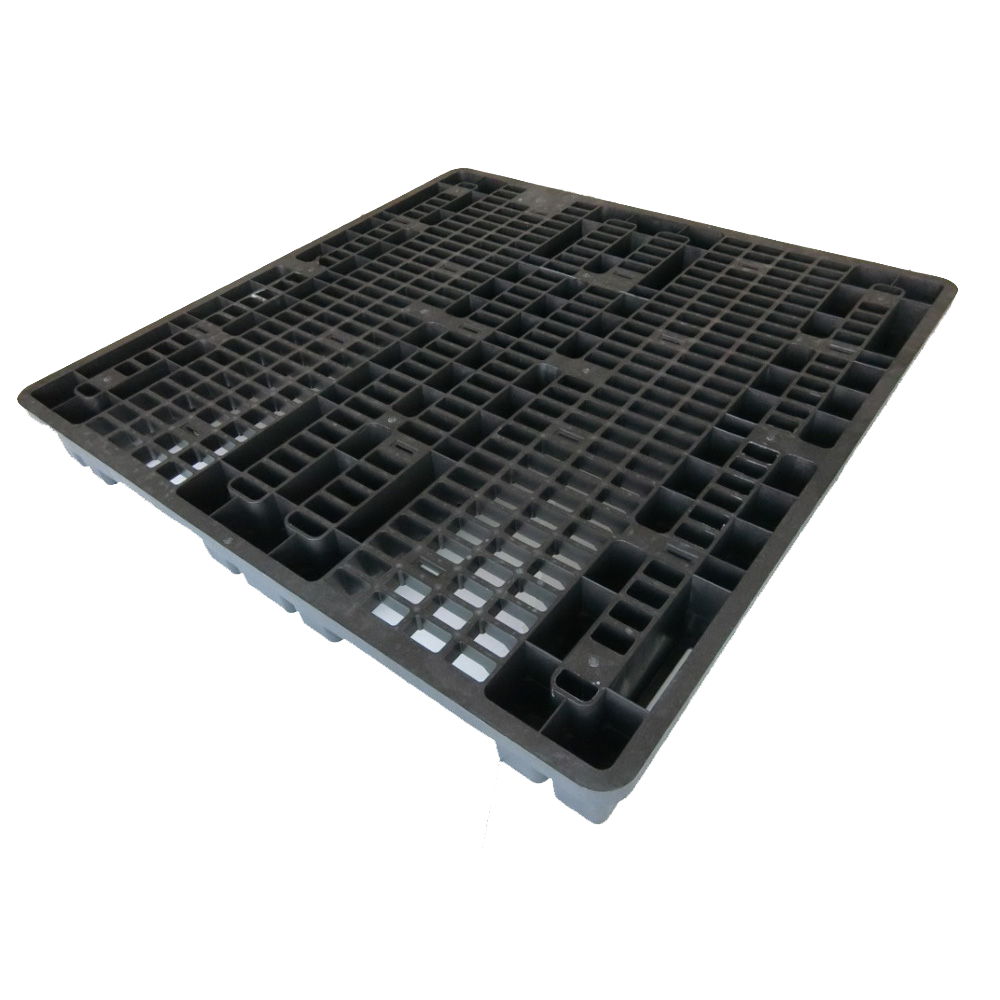

Plastic Pallets

At Prime Progression Packaging, we offer Plastic Pallets embodying the modern-day logistic marvels known for their longevity, hygiene, and recycling capabilities. Unlike their wooden counterparts, plastic pallets are resistant to moisture, chemicals, and pests, making them a preferred choice for industries with stringent hygiene standards, such as food, pharmaceutical, and healthcare. The lightweight nature, coupled with exceptional strength, makes them a cost-effective solution, reducing transportation costs while ensuring the safety and integrity of your goods.

Our Plastic Pallets are meticulously designed to withstand the rigours of various logistic operations while promoting a greener, recyclable alternative to traditional packaging solutions. They come in multiple designs and sizes, offering a versatile solution to meet the diverse needs of our clientele. The ease of cleaning and maintenance further accentuates their appeal, making them a long-term investment towards efficient and eco-conscious logistic operations. With Prime Progression Packaging's Plastic Pallets, you're not just choosing a packaging solution but stepping towards a sustainable and efficient operational framework.

Quick Enquiry form

Feel free to reach out to us for any further clarification or to discuss your specific packaging requirements. Your quest for knowledge is the stepping stone to a fruitful partnership, and we are here to guide you through every step of the way.

Product Showcase Plastic Pallets

Pallets are fundamental components in the logistics and supply chain sectors, acting as portable platforms that securely hold goods during transportation, storage, and handling processes.

Call us today!

- Size: 1090 x 1090 mm

- Material: PPC / HDPE

- Static: 2000kg unified load

- Dynamic: 1000kg unified load

- Size: 1165 x 1150 mm

- Material: PPC / HDPE

- Static: 2000kg unified load

- Dynamic: 1000kg unified load

- Size: 920 x 1120 mm

- Material: PPC / HDPE

- Static: 2000kg unified load

- Dynamic: 1000kg unified load

- Size: 1000 x 1000 mm

1100 x 1100 mm

1200 x 1000 mm

1200 x 1100 mm

1100 x 1000 mm - Material: PPC / HDPE

- Static: 2000kg unified load

- Dynamic: 1000kg unified load

Use Case

The use cases of Plastic Pallets extend across a spectrum of industries and applications, showcasing their versatility and the added value they bring to your logistic chain. Their design promotes better handling, reduced transportation costs, and a lower environmental footprint.

Call us for a live demo!

Difference between Plastic and Compressed Wood Pallets

| Compressed Wood Pallets | Plastic Pallets | |

|---|---|---|

| Material Durability | They are strong and can hold heavy loads but are susceptible to wear and tear over time. They can splinter, crack, or break under heavy stress or rough handling. | They are highly durable and resistant to damage. They don't splinter or crack easily and can withstand rough handling and extreme weather conditions better than wooden pallets. |

| Cost | Generally, wooden pallets are cheaper to purchase initially compared to plastic pallets. However, repair and maintenance costs could accumulate over time. | They have a higher upfront cost but lower maintenance costs as they are more durable and require less repair. |

| Environmental Impact | They are biodegradable and can be repaired or recycled, but wood sourcing may impact deforestation. | They are not biodegradable but are recyclable and reusable, potentially reducing waste over time. |

| Hygiene | They can harbour bacteria, mould, or pests, which might not be suitable for industries such as food or pharmaceuticals. | They are more hygienic as they resist bacteria, mould, and pests. They can be easily cleaned and sanitized, making them ideal for food, pharmaceutical, and cleanroom applications. |

| Weight | Typically, similar to plastic pallets, which might increase shipping costs. | Lighter and more uniform weight, helping reduce shipping costs and facilitating easier handling. |

How does Pallets Work

Pallets are fundamental to numerous industries for storage, transportation, and handling of goods. These steps encapsulate the general usage of pallets, yet specific procedures might be necessary based on the industry or nature of goods being handled.

Loading

Place goods evenly across the pallet to distribute weight. Stack items in a stable manner, interlocking or rotating layers if necessary to enhance stability. Ensure that the pallet isn't overloaded beyond its weight capacity.

Securing the Load

Use shrink wrap, stretch wrap or banding to secure the goods to the pallet. Apply corner or edge protectors to prevent damage to the goods and help stabilize the load. Ensure compliance with industry standards, guidelines, and regulations for pallet use

Lifting and Transportation

Use appropriate material handling equipment like forklifts, pallet jacks or conveyor belts to move pallets. Use appropriate material handling equipment like forklifts, pallet jacks or conveyor belts to move pallets.

Disposal/Recycling

Dispose of damaged or unusable pallets responsibly. Regularly inspect pallets for damage such as cracks, splinters, or broken boards and replace or repair them as necessary. Consider recycling pallets or participating in a pallet return/reuse program.

Why are Pallets Important?

Efficiency in Handling

Pallets allow for the bulk movement of goods, significantly enhancing the efficiency and speed of loading and unloading processes. By consolidating items onto a single platform, pallets reduce the time and labor required to handle individual units.

Protection of Goods

Pallets provide a sturdy foundation that helps protect goods from damage during transportation, storage, and handling. They raise the goods off the floor, offering protection from dirt, debris, and water, which could otherwise lead to spoilage or damage.

Safety

By providing a secure platform for goods and enabling mechanical handling equipment, pallets contribute to safer working environments. They reduce the manual handling of goods, minimizing the risk of injuries.

Cost-Effectiveness

Pallets offer a cost-effective solution for handling and storing goods. They are durable, reusable, and often repairable, providing long-term value and reducing operational costs.

Discover a sustainable yet robust solution for your logistics needs with our Plastic Pallets.

Contact us today to learn more about our Plastic Pallets and how they can revolutionize your supply chain operations.

Call us today!FAQs

At Prime Progression Packaging, we value informed decision-making and believe that addressing your curiosities is the stepping stone to establishing a fruitful collaboration. As you peruse through the FAQs, you will uncover insights that empower you to make well-versed choices aligning with your operational objectives. Your clarity is our priority, and we are here to guide you through the realm of packaging solutions, ensuring a seamless transition towards excellence in your logistical endeavors.

For further inquiries or to discuss your specific needs, feel free to +91-6382431185 Our team at Prime Progression Packaging is always ready to assist you in making an informed decision regarding your plastic pallets needs.

The importance of pallets is manifold and resonates through various facets of supply chain management. Firstly, they significantly enhance efficiency in handling operations. By enabling the bulk movement of goods, pallets expedite the loading and unloading processes, reducing the time and labor required to handle individual units. This bulk movement is a time-saver and a cost-effective approach to handling goods.